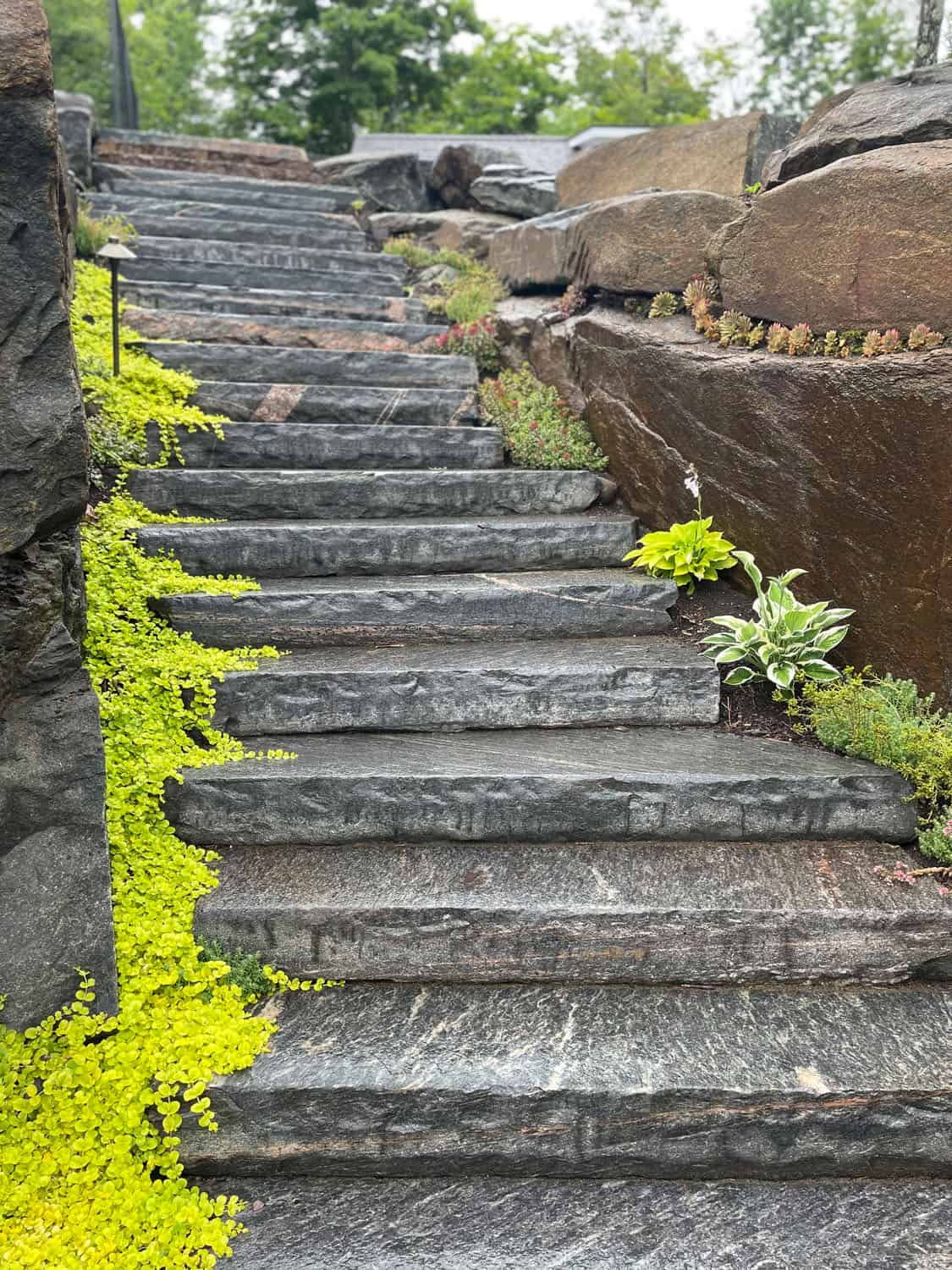

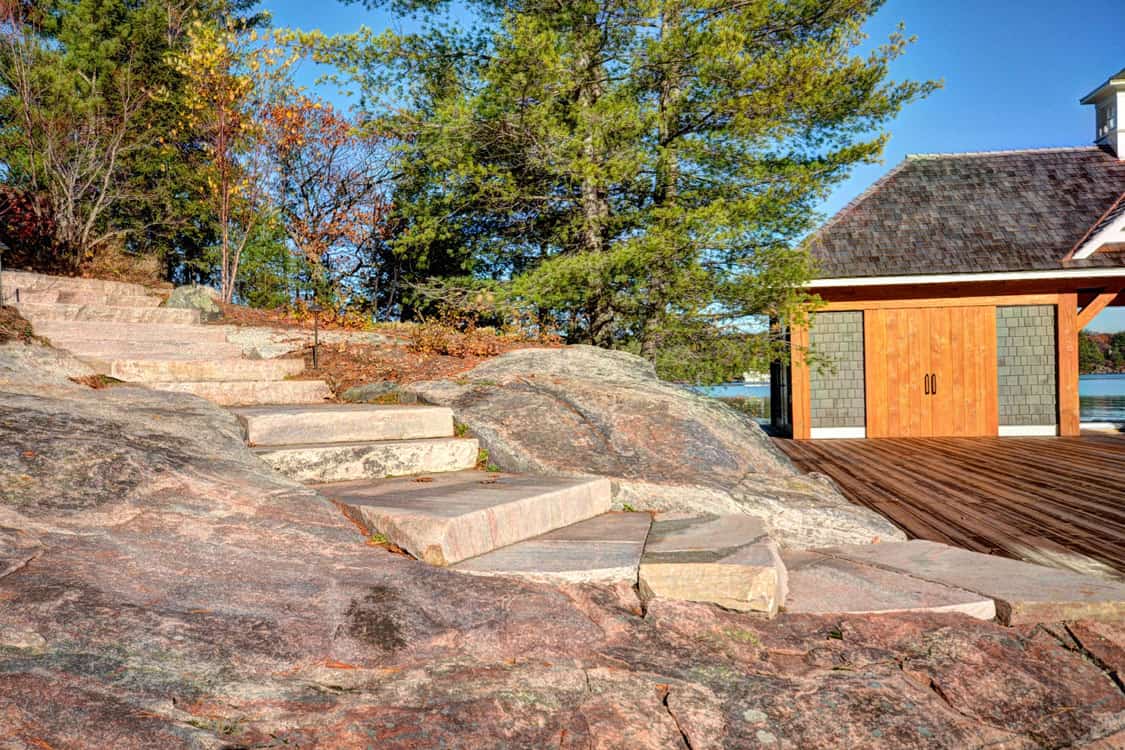

Granite vs. Limestone

In the Granite Region, north of the Severn River, we recommend sticking with granite over limestone. Limestone will stick out like a sore thumb.

Natural vs. Dimensional

This is purely subjective. Both can be used to create a natural landscape, however, for higher more vertical walls, dimensional will be more feasible and structurally sound.

Decks have open slats that cause drip lines and cause splashing of dirt up against the cladding of a building and windows. Therefore, it is recommended to install geotextile over the sub-base to help prevent weed growth, then a layer of a clear stone product. A crushed ½” crushed granite clear stone or ¾” round natural stone are the recommended products for this application. For each of their advantages, the clear stone crushed granite products bind together better than round particles and therefore do not roll as the round pea stone does. The round pea stone has a more natural, softer appearance, although the small crushed stone looks great and contemporary as well.

Creating a clean environment up against a building is important for the health and maintenance of a building. Therefore we recommend a clear stone product against a building and most commonly recommend 1-3” river rock for its aesthetic quality and ease of maintenance. It is common practice, particularly in heavily treed cottage areas, to not install eavestrough. We recommend river rock over geotextile; 1.) to create a SPLASH GUARD and keep the cladding of the building clean, 2.) to protect from EROSION and direct the water away from the building (at times, we recommend a compacted Granular base layer be placed below the river rock and graded away from the building, as the water travels through the river rock, it will travel across the compacted granular away from the building) and 3.) To MINIMIZE INSECTS. Pest control specialists believe river rock helps to deter insects such as ants away from entering a building, in particular over that of mulch and soil.

This is a personal and subjective question. The following is only our subjective view. Smaller (1-3”) River Rock has a more clean look and is easier to maintain (i.e. leaves). Therefore as an example we recommend and use it around perimeters of buildings under the drip edge. Larger (4-6”) River Rock has a more natural look. As an example, we use it as a practical use for areas with higher intermittent water flows over a geotextile as a Natural Rip Rap. You can mix in larger pieces to mimic a natural dry stream bed.

If you have high water flow on a slope in a ditch line or drainage swale, you can choose a round stone (river rock) or a crushed granite product. Product size is subjective and based on the volume of water and the steepness of the slope you are dealing with. For a lower degree of slope or lower volume of water, you can choose a smaller River Rock (1-3”) or smaller 2” clear crushed granite. For a higher degree of slope or higher volume of intermittent water, you can choose larger River Rock (4-6”) or larger 4” or 6” clear stone crushed granite.

All of our crushed stone products are Granite and manufactured at our local quarries. Granite is a superior product to Limestone. Limestone will breakdown quicker over time, will create a slimy surface when wet and will track into a house. Granite products will not breakdown, go slimy or track as easily.

All of our quarries are predominantly dark grey in colour. Some quarries have different tones of greys and colours of reds and pinks blended in. The very trained eye can spot a difference but they are all very similar in appearance after application. We do not manufacture or inventory 100% pink granite.

Although, the material recommended depends on the situation, and the larger the product, the better the water will flow. The overall most popular product is 1” clear stone. Larger material such as 2” clear stone is used in some cases with high groundwater flows, but not typical. Smaller materials, such as a ½” clear stone, will drain as well, but water will not move as freely.

We find all landscapers have their own preferred products and methods. The following is the rationale we use as we are asked this question a lot. On our projects, we typically use ½” clear below a flagstone patio, we do this for a few reasons: 1.) Clear stone does not require compaction and cut flagstone is not always a perfect thickness, and therefore, it normally requires some minor adjustments to the granular layer. Levelling with screenings or Granular M means if the top material is loose, it could compact and result in minor settling. Using clear stone, we find we can set the flagstone with less risk of future settling. 2.) the clear stone offers a drainage layer. 3.) ½” clear is easier to grade and work with than a larger diameter stone below a patio. However, for stair treads, a larger diameter stone is recommended depending on conditions. Drainage is a very important aspect of setting stair treads. If the area is susceptible to water, use larger stone, it will allow for water to flow. We have seen stair treads wash out because of a too-small drainage stone used.

Although our ½” clear stone (crushed granite) is easier to work with, we do recommend our 1” clear stone (crushed granite). The larger particles will allow for water to flow more freely in drainage areas.

Paving Stones are a manufactured concrete product and therefore have a very accurate thickness tolerance, allowing for the base layer to be accurately levelled and compacted. Therefore, Granite Screenings are easy to ‘screed’ into a smooth compacted layer and are recommended as the under layer for paving stones.

The answer is none. Technically, Granular B (Type II) is a manufactured product, such as crushed granite that passes through a 4” screen. We manufacture our Granular B Type II with 100% granite as a 2” minus product. Some contractors manufacture as a 3” minus product. The 3” minus will perform the same but is more difficult to grade and the driving surface is not as desirable as a 2” minus.

2" is ground rock used as a base layer for projects. We do not manufacture 3” Minus and recommend 2” minus. We find that the 2” minus is much easier to work with and grade. Often the base layer will remain through a construction project without fine gravel on the surface, which offers a better driving surface for temporary traffic. Some contractors offer a 3” minus or call it a Granular B Type II. This material will perform the same, but is more difficult to grade and the driving surface is not as desirable as a 2” minus. Although we do manufacture 4” minus, we use 2” minus ourselves 99% of the time when constructing a base layer, and we recommend the same.

If the area is exceptionally soft, placing a layer of geotextile down first will help bridge the material and keep the softer substrate material from coming up through into the granular layer. We recommend placing 2” minus over the geotextile. 4” minus is also a recommended product for this application, however we find the 2” minus does a comparable job and is easier to grade and work with. As well, 2” minus offers a better temporary driving surface over 4” minus.

If you have a soft area in a road, parking etc., 2” minus is by far the best product to tighten up the area. 2" minus is a ground stone that forms a tighter pack with gravel fines. The larger 2” particles together with the fines create a mesh that binds and will help bridge the soft area. The 2” minus is adequate to drive on temporarily; however, capping with a finer granular product such as Granular M is recommended. It is recommended to place 2” minus with a machine, i.e. skid steers etc., as the material is difficult to shovel.

Clear stone products can be used in parking areas. This is more of an aesthetic choice or possibly treating a drainage issue. You can use clear stone in a parking area or driveway, however, you will notice that it is noisier with traffic, more difficult to walk on and more susceptible to damage from snow removal than that of a Granular M or Granular A, that has fine particles and binds together.

We find that Granular M will compact on its own with normal traffic. However, compacting will hold the aggregate in place better and help to mitigate damage from heavy rain, as well as providing a more aesthetic surface. If you are doing a small area, a small walk-behind gas plate packer will work. Ensure it is graded and raked prior, as raking after will be much more difficult. If it is a larger driveway or parking area, packing with a large ride-on roller will put the finishing touches on the driveway. If the material is on a hill, compacting it immediately is highly recommended, even if you have to drive on it several times with a vehicle.

Granular M or ⅝” minus is the product of choice for driveways, laneways and parking areas and our best seller. It has the right blend of crushed fines with a coarse aggregate that compacts and binds together. Granular A can also be used but is recommended for higher-traffic municipal roads. Granular A is a ⅞” minus product with larger particles that have a tendency to roll to the surface and do not mesh and pack as well as the finer Granular M. This results in issues with snow blowing and snow ploughing and is less desirable to walk on.